With visual content taking over communication in the world it has become highly important to be able to create huge and impressive graphics in-house. Central to this change is the poster making machine currently providing institutions, organizations and creative practitioners with the capability to design large scale, full color visuals without utilizing the outsourced printing services. They are machines that are used to combine precision, flexibility and speed in order to fulfill the increasing demand of posters, banners, charts and other oversized graphics.

What are Poster making machines?

Poster making machines are large format printers or printing systems that are specialized to print posters and other similar graphics on different media. In contrast to regular desktop printers, which have a small size and poor print quality, poster manufacturers can deal with a width of 24 inches to 60 or more. They enable schools, businesses, and creative customers to print images of high quality and on a large scale to be durable.

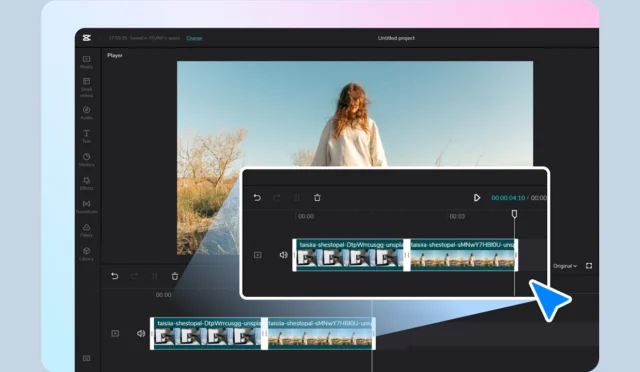

A poster making device is not an ordinary printer but it can be accompanied by a design software and workflow programs that assist the user to create a layout, control the color precision and efficiency in production. What is obtained is a smooth flow between concept to final poster.

The most important peculiarities of Poster Making Machines.

Large Print Widths

These printers accept large rolls of paper or vinyl so that users are able to print posters, banners, and wall displays in one continuous sheet, without tiling smaller sheets.

Color Accuracy and High Resolution.

Larger resolutions such as 1200 dpi or more are normally supported by poster making machines. The high-quality ink systems are used to guarantee rich colors, crisp text, and smooth effects– essential in educational charts, event graphics, or promotion.

Versatile Media Support

These machines deal with a large variety of substrates, including glossy paper, canvas, vinyl, and adhesive-backed film. This allows them to be used in indoor classroom posters and weather resistant outdoor signage.

Design Software Integration.

Most poster making machines are integrated with popular design software, or have RIP (Raster Image Processor) software to do layouts, scaling and color control. This is an integration that simplifies the production process.

Maintenance and Durability.

Designed to be used with constant and large volume printing, many of the models include self-cleaning printheads, media handling systems and diagnostic tools to reduce downtime.

Poster Making Machine can be used in the following ways:

Education

Poster making machines are of great benefit to schools and universities. The educators will be able to design educational charts, maps, and inspirational displays at any time. Efficiency is also achieved in terms of student projects, science fair boards, and event banners. This ability is in-house, and by doing so, educational institutions will save time and minimize the long-term costs.

Design and work in creative studios.

Poster making machines enable graphic designers and artists to test large scale prints, limited editions of artwork, and personal designs. The possibility to make posters of the professional level is an immediate stimulus to creativity and innovativeness.

Events and Public Spaces

Museums, libraries, poster making machines are dependent on poster making machines by organizers of events, directional signage, exhibits and awareness campaigns. On-demand printing also provides consistency and short turnaround times, even when it is necessary to make changes at the very last moment.

The benefits of poster making machines use.

Speed and Flexibility

On-demand printing also removes delays in the outsourcing process and organizations can access the high quality visuals any time they want.

Cost Efficiency Over Time

This could be expensive to start, but since posters are produced in house, the cost of outsourcing is minimized, as well as the cost of shipping and turnaround.

Creative Control

The ability to make fast revisions, experiment with designs, and customize the visuals allows users to avoid the services of external print shops.

Consistency

Poster making machines have color and quality consistency over various projects and therefore branding, educational materials or event graphics will look professional and consistent.

Best Practices on how to create an effective poster.

Calibration Periodically- Calibration guarantees accurate color reproduction.

Correct Media Management eliminates distortion, smears or folds.

Preventive Maintenance will prevent downtime such as cleaning printheads and updating software.

Design Optimization will enable minimizing ink usage, as well as media waste, and make the process more sustainable.

Future: Future of poster making machines.

With the ever-evolving technology, poster making machines are developing with environmentally friendly inks, cloud based designing, increased output speed, and automated finishing features such as cutting and laminating. Such innovations will make them even more useful in education, business and creative sectors.

Conclusion

Poster making machines are not merely a printing machine, but also a communication, creativity, and efficiency tool. In classrooms that generate learning displays, in design studios where creative minds explore novel concepts, or in the government, generating awareness campaigns, these machines enable the user to generate effective visuals safely and fast. In a more visualized world, poster making machines continue to play a crucial role in organizations that want to have control in their communication requirements in big size.