Today, it remains critical to be capable of adjusting equipment to fit client requirements in manufacturing processes, especially in present day environments of industrial societies. There is a growing trend to use the pneumatic cylinders with specific features for various industries, perfectly meeting the needs of different tasks. In industrial applications, pneumatic cylinders are used to provide the mechanical motion that is required in automation processes. In this article I aim to explain the advantages and versatility of the customizable pneumatic cylinders together with how industry and enterprise depend on industrial automation distributors.

What are Pneumatic Cylinders

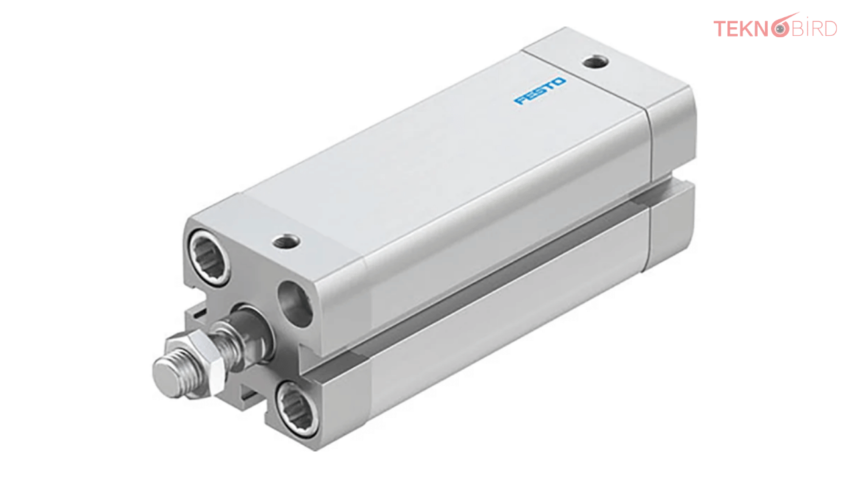

A pneumatic cylinder is a tool that employs the power of compressed air in order to create a linear movement. It comprises a piston, cylinder tube as well as other parts through which force is developed and loads moved. Standard pneumatic cylinders are intended to be standardized on a number of dimensions, including stroke length, bore size, and operating pressure, but they can be ordered in such a manner to accommodate the particular requirements of the company that will be using it.

Why Customizable Pneumatic Cylinders Matter

Standard pneumatic cylinders are a literal shift from standard off the shelf models, and can provide innumerable benefits. Among the advantages, higher customizability of these cylinders for various applications is famous: high pressure, accurate motion control, or specialized material flows, for instance. Customization can also act as a way of improving operation performances, effectiveness and safety in industries.

For instance, there are instances where specialized industries will specifically need long-stroke cylinders or indeed special cylinder seals to operate in very rough environments. Some may require cylinders that work at a different pressure from other usual pressure cylinders. This way, with an industrial automation distributor, a firm can be assured of getting a pneumatic cylinder that meets its exact needs.

Applications in Industrial Automation

In the industrial sector especially the one dealing with automation of systems and some special equipment then the flexible pneumatic cylinders are very important. These cylinders are useful in the operation of Robot movements, conveyors, materials handling, packaging, and assembly lines. Since design and operation of the said technology can be versatile, it always has the potential to improve processes and enhance outputs.

For example, in an automated assembly line, small parts can be very accurately placed utilizing a pneumatic cylinder as opposed to a human operator. In material handling, pneumatic cylinders are used in lifting and transporting loads that are physically challenging including reducing the rates of mechanical breakdown of the equipment.

That is why it is clear that the demand for specific solutions is growing along with the changes in industries. Standard and component constructions of pneumatic cylinders allow additional elements to be built into new systems, as the requirements of future-oriented technologies are met. As the distributor, enterprises are guaranteed that they are accessing the better part of the innovative development in industrial automation and solutions that meet their specification.

Key Features to Look for

When selecting customizable pneumatic cylinders, there are several key features to consider:

Stroke Length: This is the maximum distance of travel as dictated by the piston’s structure, material, make and manufacture. Cylinders can be built to different sets of stroke lengths depending on the application especially where accuracy is desirable.

Bore Size: The force that a cylinder can develop is dependent on the bore size of the particular ammunition involved. The actual dimension of a specific barrel bore dictates larger calibres yield more force and are good for heavy work.

Pressure Ratings: Based on the application, pneumatic cylinders can either be high or low pressure. The pressure ratings can be to a large extent adjusted to suit a certain pressure regime so that the cylinder will deliver optimum performance and also be safe in that use environment.

Seals and Materials: Special types of sealing materials and products can be selected to work in high or low temperatures, in corrosive environments or other application conditions. It is thus important to choose the right materials that will give the cylinders longer life and high reliability.

Mounting Options: Pneumatic cylinders offer various mountingDIRECT options, meaning that they can be adjusted to suit the rest of its incorporation apparatus. Different mounting types offer even more degree of freedom when it comes to installation.

Pneumatic Cylinder Diagram

It is therefore important to understand the principles of how pneumatic cylinders work in order to get the correct one for the job. A pneumatic cylinder diagram usually indicates the cylinder tube, piston, rod and seals as well as the air intake and release port. Looking at the diagram, individuals can gain understanding of how compressed air gets into the cylinder, forces the piston, and creates the force required to work other mechanical apparatus. Understanding of these components should be prevalent when discussing options for customization with an industrial automation distributor, so that the end product precisely fits the operation requirements.

To become more knowledgeable about pneumatic cylinders , businesses have to learn about how these cylinders work so that they can know which of the cylinders is suitable for a particular function.

How to Introduce Industrial Automation Distributor

However, to be certain that you get customizable pneumatic cylinders capable of meeting your industry needs, always work with an experienced industrial automation distributor. We work only with these distributors who have the best in terms of modern technology and materials so that they can offer you solutions that meet your needs. They can assist you with any further customizing your cylinders and can guide you on the most suitable cylinders for use in specific applications, coordinating with cylinder manufacturers, suppliers or fabricators in order to get the cylinders within the shortest possible time and at reasonable costs.

Selecting a good distributor also helps in getting the best quality cylinders since safety and efficiency in the operations which are undertaken is considered essential. One is the rationale of working with professionals in cases of real estate investments, this also helps to reduce on time wastage and in addition it also helps to avoid costly blunders.

To sum up, developed PAAs are an essential tool in industrial automation which provides the opportunity to meet the needs of customers for a high level of adaptability,high performance, and efficiency on the modern non simple control objects. Working with an industrial automation distributor proves very useful in that it guarantees businesses the provision of perfect solutions required for better operation and productivity.