Warehouse labels are a very important tool for companies that want to stay organized, be more efficient, and manage their inventory effectively. For B2B companies, the right labeling system can reduce mistakes, improve operations, and increase productivity. This guide looks at different types of warehouse labels, their advantages as well as the implementation strategies for businesses.

For complex digital display needs, Zhsunyco has developed innovative products designed specifically for small retail businesses and warehouses.

What Are Warehouse Labels?

Every warehouse needs warehouse identification labels to tag equipment, inventory items, and storage locations. Labels barcodes, QR codes, and RFID tags can be made from different materials and sizes, fulfilling the specific needs of the business. An organized labeling system helps identify products faster, track stock, and prevent lost inventory, which streamlines processes like order fulfillment. Infamous labeling system negligence can cause problems such as misplaced stock, delayed shipments, and increased inventories balance and labor costs. No business can afford these losses, so effective measures must be taken to ensure high accuracy rate with minimal disruption alongside improved operational efficiency. Losses due to negligence can be avoided by following a set labeling system, improving overall efficiency while maintaining a smooth workflow within the business. Furthermore, labels and barcodes can be integrated within the warehouse management system sometimes referred to as WMS in order to enhance real time inventory control. Compliance with legal standards dealing with hazardous materials, pharmaceuticals, or even perishable goods is heavily strained by improper tagging and labeling. Avoiding unnecessary penalties becomes possible, smoother warehouse operations become ever more constant provided there is no labeling and tagging negligence.

Various Warehouse Label Types

Warehouse labels come in various forms, and each type has its own advantage, helping keep inventory organized. Usually, labels on racks and shelves indicate their respective storage place for easy identification and retrieval of the products by the warehouse employees. These labels usually have barcodes or alphanumeric codes which help them integrate easily into the warehouse management systems. Floor labels, on the other hand, show the storage areas, the walkways, and even the areas that are off limits within a warehouse. Because they are exposed to foot and vehicle traffic, these labels are made from tougher materials that are meant to last longer and do not break down easily. Another type that is crucial are barcode and QR code labels which make scanning and retrieving information easier. In addition, QR codes have the added benefit of being able to store more extensive product information, supplier details, and even track history. For organizations that frequently reorganize, magnetic and removable labels are most suitable as they can be affixed and refitted easily without damaging the surface. On the other hand, RFID labels are a more modern way of tracking using electromagnetic fields to transfer data without needing direct scanning. This would be very useful for huge warehouses that have a lot of stock coming in and out because this makes real time tracking possible with little human action.

NFC (Near Field Communication) labels is yet another innovation in warehouse labeling technology. Now, warehouse employees can get product information just by tapping their smartphones on the label. This technique increases productivity by removing the requirement for more scanning equipment. The appropriate category of warehouse label to use is influenced by the type of business, the area of the warehouse, and the desired level of automation.

Benefits of an Effective Warehouse Labeling System

Labeling is very important in how your warehouse and business functions. The primary advantage of a good labeling system is improved inventory accuracy whereby labeling storage areas ensure that more products are identified and recorded. The good recording results in good stock control; there are few chances of overstocking or under-stocking the products. Moreover, labeled exits and partitions enable faster retrieval of products, which leads to quicker order fulfillment, increases productivity, and enhances warehouse productivity. Another advantage is increase in order accuracy because barcode and RFID labels eliminate the chances of data entry errors and returns are reduced. Clear labeling of warehouses also helps businesses optimize the utilization of the space available. Safe marking of the hazardous materials, pathways for walking, and safety zones allow other people to easily and quickly know the marked areas. There are improved workflow efficiency and meeting of the industry regulations and safety standards. In the long term, reduced labor costs, lost inventory, and productivity all add up tremendously to cost savings.

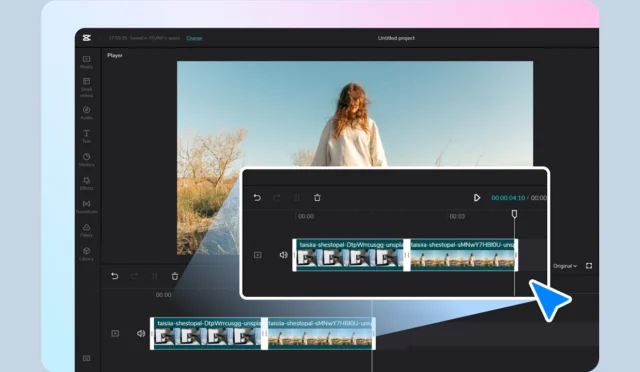

Adopting computerized labeling systems allows businesses to improve tracking, increase warehouse productivity, and ensure automatic inventory system synchronization.

Recommended Strategies for Using Warehouse Labels

To ensure the most value and utility from warehouse labels, businesses are advised to observe a number of recommended strategies. It is very important to select the proper label material because different warehouse environments have varying levels of durability. For instance, facilities that experience a lot of humidity or temperature change may require weatherproof labels, while warehouses that use heavy machinery may need industrial-strength adhesives. Also, standardization of label designs across all storage areas enhances readability and improves scanning and data collection. Businesses could also consider using color-coded labels to identify product types, storage areas, and priority shipment areas, making it easier to locate materials in the warehouse. Using digital technology can also improve labeling efficiency. Zhsunyco has digital display solutions that update in real-time which helps reduce manual labeling and provides accurate inventory information. https://www.zhsunyco.com/ru/digital-price-tag/ Regular label audits is another practice that many people neglect, but it should not be the case. Labels can fade, and bosses must routinely inspect them to be sure they are not getting exposed too much to the surrounding environment and simply being worn out due to being handled too much. Constantly checking and replacing ensures that labels are clear and serving their purpose while keeping the logistics and warehouse the way they should be. Instruction sessions to make warehouse labeling understood by all employees is equally important, so workers know what the labels are, how to use them, and how to maintain them.

Equally, using automations like AI-integrated barcode scanners and automated label printers can greatly improve efficiency and accuracy in large scale warehouse operations. Meanwhile, attaching warehouse labels to IoT monitoring devices enables live inventory tracking, minimizes losses, and improves supply chain management.

Final Thoughts

Labels have the potential to improve the inventory and organization of any operation. With the proper label types, industry best practices, and B2B digital solutions, companies can improve their logistics and supply chains considerably. Labeling systems are essential for efficient stock management, reducing re-work, wasting space, and enhancing productivity while minimizing costs. Zhsunyco has cutting-edge digital displays designed to work side by side with conventional systems, offering businesses new ways to streamline labeling processes and enhance real-time visibility of inventory and integrated advanced warehouse management systems. A label-centric approach solves a host of challenges and helps keep an organized warehouse. Embracing the development of smart labeling solutions that automate processes and digital transformation provides an edge to businesses as warehouses evolve. The fast-paced transformation of technologies of warehouse management opens new avenues for error reduction, optimization of workflows and faster order processing in order to exceed customer expectations.