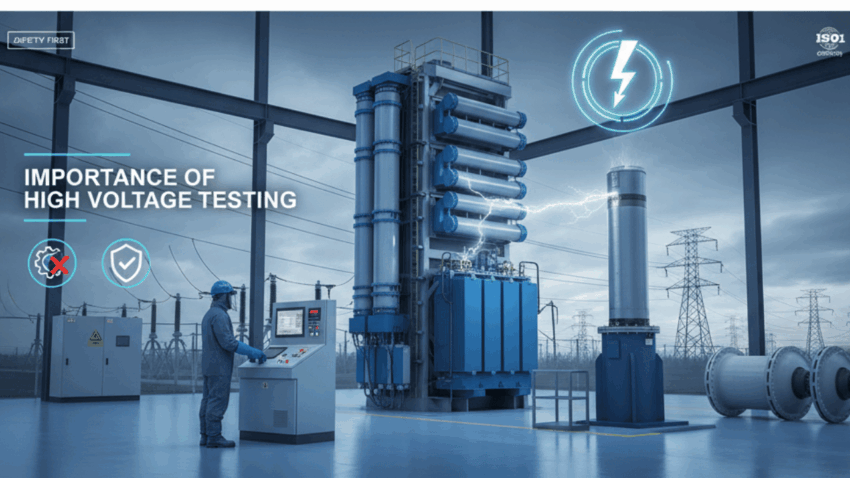

Importance of High Voltage Testing

Safety Assurance for Electrical Systems

The safety of electric systems needs High Voltage Testing of Insulation Faults, high voltage conducting systems, and other components, as full dead and live testing with validation, elimination, and mitigation of hazards to prevent electrical shocks to people, equipment, systems, and situations, which ends up serving as a big safety net for equipment and people.

View high voltage test equipment manufacturers and suppliers – DEMIKS details to get into the details.

Sustained Equipment Operational Productivity

Scheduled and preventive maintenance needs to be practiced, including high voltage testing, regular maintenance, and others, to reduce the chances of sudden failure while reducing maintenance costs and increasing electrical equipment life. The number of equipment failures is an important factor for loss of production and failure in production systems that have a high dependency on electric systems.

Legal and Restrictions

Legal compliance for testing of high voltage electrical systems borders on avoiding regulations or standards as international, IEEE standards, ISO, IEC, and many, compliance avoiding not just the manual loopholes in regulations, rather covering the safety and effective testing in any situation of the regulations so that compliance can show to the level of safety coverage and Quality control, covering all breach expenses, reputation and financial expenses covering for compliance.

Types of High Voltage Test Equipment

Discrete high-voltage test systems are essential for evaluating the effectiveness and accuracy of apparatus using high-voltage equipment. They are built to imitate actual operating scenarios, enabling engineers to diagnose issues, confirm the function of the insulation, and determine the durability of the apparatus. High voltage test systems are utilized across the power generation, transmission and distribution industries. They are also applicable in the production of high-voltage apparatus. Their adaptable nature proves ample for use in the commissioning, servicing and quality control of high voltage facilities.

Identifying High Voltage Detectors and Their Use

High voltage detectors are devices that serve the primary purpose of establishing the presence of voltage in an electrical system. They are vital to the safety of the operator, especially when the operator is carrying out installation, servicing and repair of equipment in high voltage systems. High-voltage detectors have sensors that alert the operator of a charging circuit. These tools are used in substations, power transmission lines and industries for the safety of the operators so as not to tamper with live apparatus as well as for safety compliance.

Transformers for the Instruments used High Voltage Testing.

In high voltage testing, instrument transformers, more specifically, current transformers and voltage transformers, are of utmost importance. High voltages and currents are attenuated in an instrument transformer, such that they are measurable without any operational threat. Without transforming high voltages and currents, protective relays, metering systems, and diagnostic systems can’t ensure seamless management of an electrical system’s flow. The instrument transformers are accurate enough that the continuous high voltage tests made upon an electrical system are safe. Hence, it ensures that the electrical systems are functioning optimally.

Industry Applications of High Voltage Testing

Testing Cables in Power Distribution

The testing of power distribution cables and energization cables is done with the assistance of the high voltage testing method. This involves the analysis of electric power cables with an auxiliary method of high voltage testing. Power cables testing is done in order to ensure the effectiveness, safety, and durability of the power cables. This also includes identifying defects such as insulation breakdown, partial discharges, and other shortcomings. The testing of cables on a regular basis enables the earliest detection of errors, which greatly minimizes the chances of unscheduled outages. This also signifies the reliable and uninterrupted flow of electric power. VLF testing, tan delta measurement, and withstand testing are a few methods used to test the power cables on high voltage level.

High Voltage Testing of Systems of Renewable Energy

The elements of a system of renewable energy, for instance, a wind farm or solar power plant, also require high voltage testing for the purpose of safety and effectiveness of all components. Converters, transformers and other lines of transmission that are subjected to high voltage electric stress are within the scope of high voltage testing. It also spans the lower limits that are present from the solar farm. The elements of wind power are subjected to high electric stress, similar to the range of the a wind farm. The load conditions are quite variable in the case of renewable energy. This is the main reason as to why the components need to be able to withstand sudden bursts of energy. This also assures the stable energy output and the protection of the main components across these renewable energy structures.

Utility and Infrastructure Applications

Power network reliability and any associated enhancements, as well as any use of infrastructure, necessitate high-voltage application testing. Utilities, like substations, transmission lines, and distribution networks, routinely undergo high voltage testing like dielectric strength, breaker, and insulation resistance testing to evaluate safety and operability. Systems infrastructure maintenance and compliance with service interval and industry service testing requirements depend upon dielectric strength, breaker, and insulation resistance testing. System failures cause escalated maintenance and service interruptions to customers, which further escalates service demand by homes, industries, and businesses.

Safety Standards and Regulations

Background of Safety Protocols in High Voltage Testing

The safety of personnel and equipment in high voltage testing is critical and is achieved through strict safety procedures. OSHA, IEEE, and IEC, among other organizations, precisely define procedures that need to be followed to minimize the safety issues involved in performing high-voltage work. High voltage testing, in accordance with the standards set, is carried out to minimize the risk of shock, arc flash, and damage to apparatus. Norms of the standards set mostly concern the training of personnel, the checks done on equipment, and the limits set on the voltage being tested.

Personal Protective Equipment

All high voltage personnel must have seamless protective equipment (PPE) to avoid injury during voltage testing. Notable ones are insulation gloves and sleeves, arc-rated clothing, safety glasses, dielectric boots and slippers, and hard hats. All forms of protective equipment must be visually inspected regularly and certified to be in proper working order. Protective equipment must be, to a conclusive extent, rated through laboratory tests to check and assure their safety during high voltage procedures.

Best Practices for Safe Testing Procedures

Avoiding risk when carrying out high voltage testing requires the use of best practices. Before carrying out the test, confirm that all apparatus are correctly grounded, and that there is sufficient distance from live parts. Ensure that the testing instruments are set and calibrated, and that there is an unambiguous communication structure within the test group. Communicate the need for signage and physical barriers of a controlled area to warn colleagues of a potential risk. Conducting routine safety checks and establishing a culture of caution for emergent situations are also important. Best practices suggest that the risk to people and the facilities is reduced during high voltage testing when test practices are used.

Tips for Selecting the Right High Voltage Test Equipment

Understanding the Purpose of Testing

Prior to the selection of the appropriate high-voltage test equipment, the functionalities of the application must be evaluated and understood. Determine the type of test voltage and testing to be performed, be it AC or DC testing, insulation testing, or discharges of any type. Establish the parameters of the environment, be it indoors, outdoors, rugged conditions, or any conditions that may require portable models. Understanding the utilization of the equipment will help determine the suitability of the equipment to the application.

Most Important Aspects of Testing Equipment

Various important aspects will determine the appropriate high-voltage test equipment. It is important to select the devices that have a wide range of measurement capacity, high precision, and consistent dependent functionality. Equipment that has over-voltage protection, automatic shut-off, and easy operability can improve the safety of the equipment. Modern equipment must have devices compatible with modern collection and analysis data tools, USB, or wireless connections.

Assessing Manufacturer Support and Service

In addition to the equipment, while analyzing manufacturer support and service, it is crucial how manufacturer’s respond. A company that deals in machinery ought to provide proper equipment, training, and prompt support, in addition to the comprehensive customer user guide. What prolongs the life of testing equipment is the warranty offered, and those that offer spare components that are not very difficult to access. Also, does the manufacturer offer recalibration and continuous, proactive technical support to maintain equipment in a desired state throughout the entire life of the device? These services would further ease your equipment lifecycle management.

Recent Technological Advancements in High Voltage Testing

Improvements in High Voltage Test Systems

High voltage test systems have evolved in last few years in their efficiency, precision, and reliability. Modern test devices automate parts of their operation, thus configuring test setups faster and minimizing human error. Their simplicity and light weight make them portable, an important criterion in mobile systems. Their use of advanced materials and techniques also enhances their durability and sustainability, which contributes to an evolving industry.

Role of Internet of Things in High Voltage Testing

The Internet of Things (IoT) integrated into high voltage test systems improves remote functioning, real-time data collection, and system monitoring. IoT test systems use predictive analytics to anticipate failures of system components. These systems offer cloud analytics for users to access systems remotely. This promotes remote working and collaboration. IoT devices eliminate silos in the system, improve operational visibility, and create better management of high voltage testing resources.

Trends in Diagnostic Testing Technologies

The evolution of diagnostic testing technologies continues to focus on precision and non-invasive methods. The differentiation of partial discharges and condition monitoring is obtaining deeper levels of sophistication and providing greater insights into the status of the electrical system. More sophisticated plasma electrical discharges and non-invasive method monitoring employ thermal or acoustic imaging as the norm. In the same way AI and machine learning modules are used, diagnostic systems are more complex and multi-tiered, making the electronic systems more rigid, and the systems more rapid in decision-making. There is minimal time and expenditure spent within the industrial paradigm as the industry is gearing up its standard operating procedures towards augmenting its diagnostic prowess.

Common Challenges in High Voltage Testing

Addressing Partial Discharge Testing Issues

Assessing high-voltage air-insulated equipment requires partial discharge testing to verify insulation integrity. One of the main concerns, however, is the classification of genuine partial discharge signals as noise. Shielding and advanced filtering must be utilized to get any plausible results. Moreover, knowing the precise testing environment and equipment allows engineers to devise ways to control interference during testing.

Dealing with Environmental Conditions

High voltage testing results can be affected by environmental conditions like temperature, humidity, and airborne pollutants. Tests should ideally be done in controlled conditions to guarantee precise and repeatable results. In the field, these high-voltage tests should factor in the environmental conditions via rugged equipment or mathematical adjustments. Programmed and manual weather monitoring can make sure these protective processes and appropriate equipment or adjustments are utilized.

Maintenance of Equipment Calibration and Accuracy

Maintaining the precision and calibration of the high-voltage testing equipment is extremely important for obtaining credible results during high-voltage testing. Periodic calibration against the ‘recognized standards’ helps ensure the instruments do not drift over time. Ensuring that a maintenance schedule for testing tools is in place and purchasing accurate diagnostic instruments can help minimize the potential for errors. Furthermore, training personnel on standards and practices on equipment can also improve the precision and dependability of results being produced in the testing phases of the process.