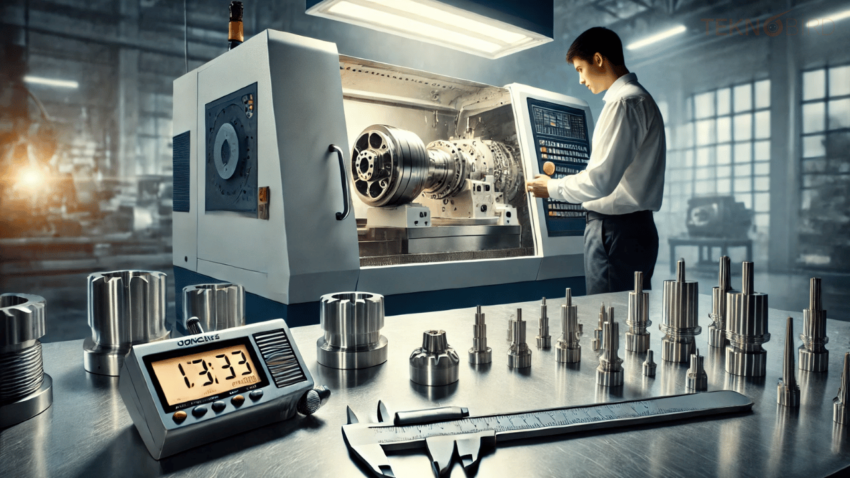

Turning with CNC has also been adopted as a vital method of precision machining to meet the ever-rising demand of manufacturing sophisticated, highly accurate parts. Underlying this success are CNC turning suppliers who can deliver approaches for Turnkey parts production. Being the key machined parts supplier, these companies serve various industries such as aerospace, automotive, medical, and electronics industries. The focus of this article is in understanding how CNC turning suppliers contribute to the development of precision engineering.

Bringing Enhanced CNC Turning Solutions

CNC turning suppliers stand out by using highly developed machines and technologies to address the high expectations of precision engineering. For example, advanced contemporary CNC machines, including a multi-turret or multi-table design, live tooling, and high rev/min, helped suppliers to achieve finer geometries. These features facilitate the creation of components with thin wall thickness, intricate geometries required for applications in aerospace, medical equipment, or electronics.

Another leading characteristic is the use of CAD/CAM software among the suppliers in question. These tools help us when moving from design to production by providing the best paths that the cutting tool should take, they also reduce possible errors and Cutting waste. The role of automation is huge since it helps suppliers to control a large number of production cycles with identical characteristics. The companies that are involved in the business of manufacturing and supplying machined parts are always able to provide their clients with high quality parts that can meet or even surpass benchmark set for them in the industry. By doing so, they are always in a position to adopt and implement advanced technological solutions to their operations, hence making them remain relevant in the competitive and constantly evolving market for precision engineering.

Offering Flexibility Via Material Knowledge

Specialization amongst the material types is one of the key parameters of a competent provider of CNC turning services. These suppliers have to prove their metallurgical versatility, wherein they would be expected to be equally capable of working with aluminum or with titanium or with engineering plastics such as PEEK or polycarbonate. All of the materials have their advantages and disadvantages – some are easier to machine than others and it takes a lot of engineering knowledge to know which one fits which application.

For instance, aerospace clients may need materials for increased strength and lightweight because weight is a critical factor affecting performance. At the same time, the medical industry could require biologically non-toxic plastics for things such as implants or surgical tools. The machined parts supplier with deep knowledge of how to choose materials guarantees that parts for the equipment perform their intended function and are safe. In addition, suppliers may perform material testing and analysis to assure that a material is appropriate for the application and provide substitutions if needed. Through the ability to adapt to various applications and industries to prove the CNC turning supplier gives the industries confidence needed in ordering the components since they will be customized to the industries in question by the supplier.

Maintaining High Quality Assurance Guidelines

One of the most important aspects of any CNC turning supplier’s operations is quality control. Highly technical industries involving precision-engineered components call for almost perfect parts that fit their requirements and typically have tolerances in micrometers. This is accomplished through tightly controlled quality management programs that are maintained throughout the supplier’s entire manufacturing process including raw material acquisition and final product inspection.

High-quality first-tier suppliers of vehicle manufacturers employ quality control equipment including the CMMs laser scanner optical inspection equipment. They provide critical control over part dimensional stability and overall parts uniformity for product runs that may entail the manufacturing of thousands of identical parts. Enhancements such as those recognized by ISO 9001, AS9100, or ISO 13485 assure the customer of the conformity to the highest standards of a supplier. As a machined parts supplier, there is one important principle – to avoid as much as possible, having to deliver parts that are defective, waste resources, and erode customers’ confidence. It keeps suppliers to the effect that they give consistent quality products that meet their requirement and are suitable for even sensitive projects such as aerospace and medical industry where the smallest variation will have drastic effect on the efficacy of the product.

Offering Customization and Scalability

. flexibility and ability to meet the specific client needs are important features of the leading suppliers of CNC turning. Components to be integrated must therefore be custom made to meet the client’s needs from prototyping to large scale production. Those that are able to satisfy these particular needs and offer flexibility and handle company variant needs offer great value for itself especially in dynamic environments.

For example, prototyping services enable clients to prove design concepts while still experimenting with product usability. Vertical integration, suppliers have enough capacity to handle both low and high levels of orders in terms of production. A product supplier who can provide these services, can always be prepared to accommodate their customer’s shift in design, production, or material choice. Other services that include assembly services, and surface treatments and packaging are an added advantage since they reduce the supply chain burden to the clients. This and the willingness to design bespoke solutions make CNC turning suppliers invaluable when it comes to precision components.

Driving Innovation and Cost Efficiency

CNC turning suppliers occupy a strategic position in changing dynamism and value stream in precision engineering. Automation, robotics, and AI-driven machining processes are currently embraced to paint the picture of efficiency and, in the process, keep insisting production costs down. This brings about early completion of projects; increased efficiency and reduced scrapping of material as it fulfills the anticipated goal of both the retailers and their suppliers.

Suppliers are also a source of information regarding design improvements; materials and manufacturing process to be adopted. This makes the delivery of improved performing components possible for clients and at the same time reduces costs. For instance, a machined parts supplier can advise the buyer on using different material or ask them to redesign their part in a way that it will require less machining time. To ensure that virtual instrument solutions are both innovative and affordable, CNC turning suppliers foster competitive advantages for their clients in their target industries. This focus on continuity and productivity as elements means that they are prominent in advancing precision engineering.