The CNC acrylic machining service is extremely important for crafting highly precise parts that possess intricate specifications, especially in various industrial sectors. For optical clarity and thermal stability, engineers and manufacturers tend to prefer polymethyl methacrylate (PMMA) acrylic. Among various advanced technologies, acrylic machining is done through high precision CNC (Computer Numerical Control) machining which makes sure that custom parts are reliable and accurately manufactured.

View Top Acrylic Machining Services Provider in China – Hopeful details to get into the details

For the benefit of engineers and manufacturers who are approachable through this blog, we will discuss the benefits, processes, applications, and design considerations for acrylic machining services.

What is Acrylic Machining, and Why is it Important?

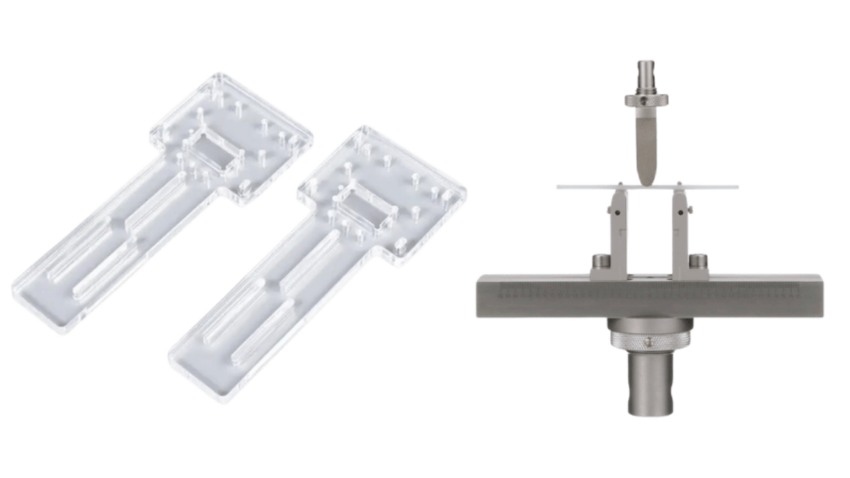

Acrylic machining entails the shaping and fabrication of acrylic blocks or sheets into specific custom parts and components. Acrylic parts can be custom-manufactured for specific applications using precision CNC routers, mills, and lathes.

As in the case of other processes, acrylic machining also has its importance and advantages. Acrylic machining possesses tight tolerances, excellent repeatability, and superb finishes while maintaining the acrylic qualities of being lightweight, optically clear, and durable.

Understanding the Basics of Acrylic and Its Properties

Acrylic also known as PMMA is a thermoplastic and is often referred to as plexiglass. Acrylic possesses several defining traits which include high impact strength, excellent weather resistance, and exceptional optical clarity. It is commonly used for glass and polycarbonate because it is transparent, yet rugged.

The main properties of Acrylic include:

Optical Clarity- Transparent acrylic can be as transparent as 92%, making it more optically clear than glass.

Durability- Acrylic is known for having a high level of impact resistance which makes it perfect for industrial and protective purposes.

Thermal Stability- Works well in temperature ranges of -40 degrees Fahrenheit to 194 degrees Fahrenheit.

Lightweight- Acrylic is almost half the weight of glass, which reduces the overall weight of the application.

These properties make acrylic a preferred material for industries ranging from automotive to medical equipment.

Why Choose Acrylic Machining Over Other Materials?

When compared with other materials like polycarbonate, ABS, and glass, acrylic machining has a number of benefits. Some advantages include:

Custom Marking: Custom designs can be created with CNC machining, making acrylic to meet exact specifications and application requirements.

Cost Effective: Acrylic machining is, in most cases, less costly than working with metal and glass materials.

Superior Optical Clarity: Acrylic has better optical clarity than most plastics, making it a good choice for optical components, displays, or covers.

Ease of Machining: Unlike harder materials, acrylic is easier to cut, drill, and engrave without compromising its structural integrity.

Acrylic Machining in Various Industries

For many industries, acrylic machining is of great use due to the material’s performance as well as the material’s appeal as an optical feature:

Aerospace: Internal trim components, light covers, transparent instrument panels.

Medical: Display screens, diagnostic equipment parts and acrylic lenses.

Automotive: Interior trim parts, dashboards and windshield components.

Retail: Signage, custom kiosks, and point-of-sale displays.

Electronics: Optical components, protective cases, and screens.

How Does CNC Machining Work for Acrylic Materials?

CNC machining employs computers and software to automate the processes of cutting, drilling, and turning to produce accurate and detailed acrylic parts. Compared to traditional machining, CNC machining reduces labor and enables better automation, repeatability, and custom complexity of design.

CNC Machining Procedures

Designing

The first step uses CAD (Computer Aided Design) software to create digitally the required acrylic part.

Programming

The CAD design is then turned into CAM (Computer Aided Manufacturing) code, which gives a CNC (Computer Numerical Control) machine instructions for executing specific tasks.

Machining

Operations like cutting, routing, milling, and polishing are accomplished properly through CNC tools based on the previously set parameters.

Final touches

Buffing and polishing bring clarity and smoothness to the acrylic part, thus improving its overall appearance.

Advantages of using CNC Machining Services for Acrylic

Accuracy: Acrylic CNC machining tolerances are very close, even to +/-0.005 inches.

Consistency: CNC equipment consistently reproduce accurate designs, perfect for mass production.

Complex designs: Patterns, grooves, and even engravings can be done with advanced machining equipment.

Fast Turn Around: While retaining quality, CNC machining greatly shortens lead times.

What different acrylic machining services are available?

The machining services offered for acrylic differ based on the requirements of the projects. Knowing them can assist you in selecting an appropriate method.

Classifications of CNC Acrylic Machining Services Offered

CNC Milling

Best suited for complex 3D shapes like contoured sculpted forms along with more open structural components such as frames or brackets.

CNC Turning

Best suited for pieces that are round or cylindrical such as tubes, rods, and optical discs.

Laser Cutting and Engraving

Best suited for making detailed cuts and complex designs with considerable accuracy while preserving material.

Polishing and Buffing

This improves the surface and makes it clearer optics while increasing the aesthetic value.

Custom Fabrication Solutions for Acrylic Components

Custom fabrication options enable forming, bending, bonding, and assembly to provide fully integrated solutions tailored to meet project needs.

How to Choose the Right Acrylic for Machining

Identifying the Ideal Acrylic Material for Your Project

When choosing an acrylic material for CNC machining, keep in mind:

Physical Requirements: Strength and durability as well as weight-bearing tolerance.

Application Environment: Contact with UV light, temperature, or chemicals.

Aesthetic Needs: Options of color, surface finish, and level of transparency.

PMMA vs. Other Plastics

As compared with other types of plastics, PMMA is the only one that allows for high optical clarity, UV resistance, and versatility in machining, making it an ideal CNC machined parts candidate.

Design Tips for Optimizing Acrylic Machining Projects

Though efficiently improving machining processes while maintaining the quality of the final product, design considerations need to take into account the following:

Walls should permit even stress distribution so they are thicker than the other walls.

Caution when dealing with sharp corners as they are prone to stress cracking.

Consistent tolerance limits promote stress relief during assembly.

Advantages of Using Acrylic in Industrial Applications

Durability and Flexibility in Manufacturing

Acrylic parts can endure force and lend themselves to various shapes without the risk of fracturing or distortion.

Their Optical Features are Essential to Products

Because of the high level of light transmittance, acrylic is perfect for use in lenses, signage, and protective panels.

What to Expect from Acrylic Machining Services

Quality Assurance and Tolerances in Acrylic Machining

For the machining of acrylics, practices include verifying the accuracy of measurements, examinations of surface finish, and tolerance checking.

Time of Delivery and Cost Factors

The lead time depends on order quantity, complexity of design, processing steps involved with the order, and any additional finishing steps. When it comes to precision and speed, cost-efficient solutions are often found in CNC services.

Elevate Your Acrylic Machining

For engineers, product designers, and even manufacturers, acrylic machining services provide unique and unrivaled accuracy. The ease of CNC machining further complements the natural acrylic properties. Thus augmenting the possibilities of innovation in your projects.

Get in touch with a reliable CNC machining service today if you seek precision tailored to your design requirements.