Shrink tunnels are critical in contemporary packaging since they provide a perfect way of wrapping products. This article discusses these aspects and why it is important for packaging companies to deal with the leading packaging equipment makers.

Shrink Tunnel Machines

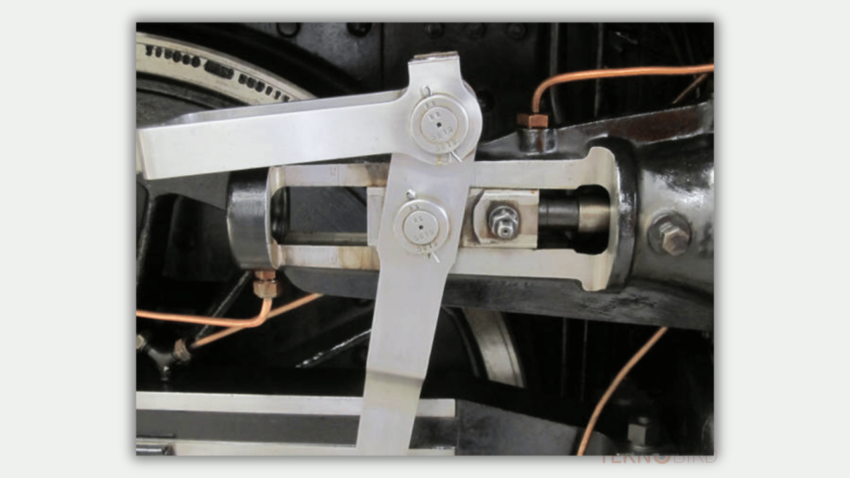

Shrink tunnel machine is used to apply heat on shrinkable plastic film on products; this offers the products a secure and professional appearance. In this one, there is a heat tunnel and belt to make certain that the film conforms to the alleviation of every product. Shrink tunnel machine manufacturers combine quality with the production of durable machines.

Advantages

Shrink tunnel machines present the following advantages that improve the aspect of packaging: This serves as a security on the products from dusting, wetness and handling which is important to sectors such as food, drugs, and electric instruments. The shrink wrap on the convalescence blanket also has a snug fit that enhances the product’s aesthetics, thereby increasing consumers’ trust and subsequent purchases. Further, these machines help in wrapping where manual efforts are eliminated, work is done faster, and fewer mistakes are made.

Multiple uses

Shrink tunnel machines are multi-purpose and can be utilized with any kind of product. In the food industry they seal food such as baked products and beverages to ensure that the food is fresh and protected. In the pharmaceuticals they offer the security of a tamper evident seal in medicines and related devices. Laptop manufacturing companies apply them to shield such devices from dust and humidity. That is why retailers can employ them for product set multiplex and for improved visualization. These diverse application requirements are met by packaging equipment manufacturers who provide best-suited equipment for the specific job to be done.

Right for You

Shrink tunnel machines are chosen according to the size of the product, the kind of product, the rate of production and the packaging parameters. It is advised to opt for the packaging equipment from reliable manufacturers and suppliers as you will get the best advice and the best equipment. Five parameters for the choice of a machine include speed, compatibility with the film, and compatibility with your production line. When it comes to buying shrink tunnel machines, one must engage experienced manufacturers who will provide a machine that fulfills the set needs and optimizes packaging processes.

Maintenance and Practices

This shows that maintenance is very important so that the shrink tunnel machines will be able to work well and also for them to have a long life span. Execute proper maintenance such as periodic checks, cleaning, greasing or oiling of the right parts and replacing of damaged and worn parts as often as needed. Hence, it is seen that effective maintenance prevents variation in the packaging quality. Manufacturers of the packaging equipment offer servicing services to keep your machine in a good condition.

Therefore, shrink tunnel machines are important for better packaging and provide fantastic safety, appearance and effectiveness. Since businesses deal with well-established organizations of packaging equipment manufacturers, they are always assured of out-of-the-box machines that fit the packaging operations, making the businesses successful. Purchasing a shrink tunnel machine enhances the product defense, packaging, and processing protocols’ efficacy.